Pickling/Passivation

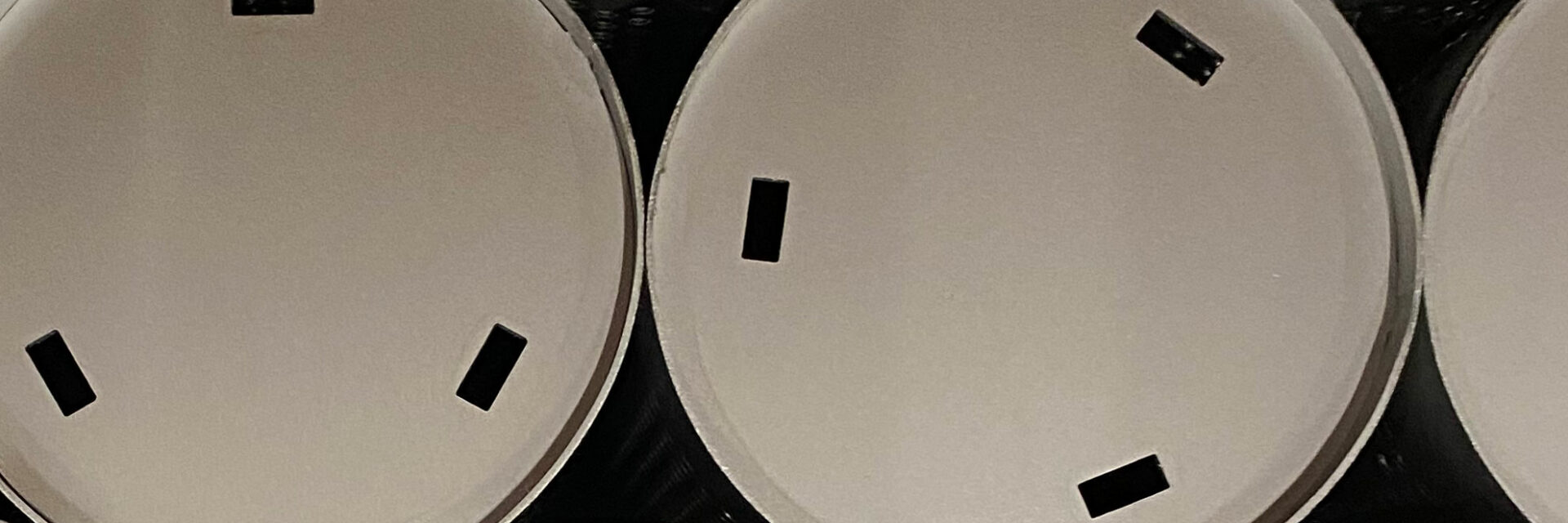

Pickling and passivation are applied to stainless steel in a single treatment, which cleans welds and any annealing colours. The chromium oxide skin is restored, making the surface passive and thus corrosion resistant again. The result of this process is an even matt appearance. It is sometimes necessary to treat welded products with a steam cleaner. This removes the welding discolouration that has been pickled loose.

Request a quote

The pickling and passivation process is designed for austenitic stainless steels. We can also passivate other alloys. However, we sometimes have to use different pickling/passivating solutions for this. Because non-austenitic stainless steel deteriorates quickly in the standard pickling and passivation bath, the type of alloy should be known in advance.

If the end result has high visual requirements, we take special measures. In such cases, the products should not be touched by hand after the treatment, as the passivated stainless-steel surface is prone to staining. The products must also be packaged individually. Galvamé uses a special process exclusively for applications with high visual requirements.

- Applied to stainless steel

- Cleaning of welding discolouration

- Restoration of chromium oxide skin and corrosion resistance

- Even matt appearance

- Type of alloy important for treatment selection

- Special process for high visual requirements, including individual packaging