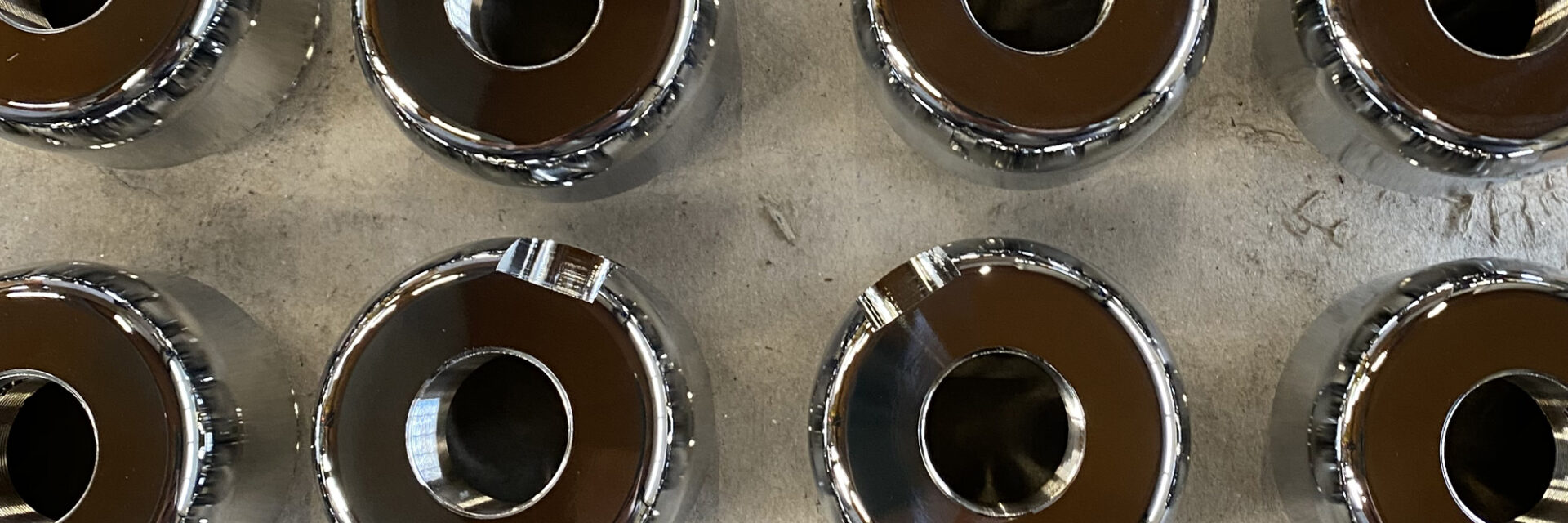

Chrome plating

Chrome is blue-white in colour. Chrome plating is used for embellishment and corrosion protection. In decorative chrome plating, a nickel undercoat is always applied first. The thin chromium topcoat then applied gives the product a different colour and makes it corrosion and abrasion resistant.

Request a quote

Corrosion resistance of the base material is achieved through the nickel undercoat. As described under electrolytic nickel plating, a duplex (double) nickel layer achieves the best corrosion resistance.

The nickel layer can be matt, semi-bright or bright and determines the appearance of the chrome coating deposited on it. If the product has high visual requirements, it should be ground and brushed or polished before nickel plating and chrome plating. This is because any imperfection in the base material is accentuated, especially with a bright nickel coating. While scratches and texture are filled by the nickel layer to some degree, they generally remain visible.

- Aesthetic, hard-wearing coating with blue sheen

- Does not oxidise in air, long-lasting appearance

- Finish possible in matt, semi-bright or bright

- Pre-grinding and polishing give the best results

- Layer thickness from approx. 0.1 µm to 0.5 µm